GUIDE - Tie Rod Length Measurements

GUIDE - Tie Rod Length Measurements

Tie Rods – Tying up loose ends

How to identify and measure tie rods or Racing go-kart use.

I am often asked the question “How do I go about ordering the correct length tie rods from your website?” so I’ve decided to write this informative but straight-forward guide focussed on measuring for both existing tie rods, and where you may be fabricating your own chassis or where tie rods are missing from the chassis.

The guide includes:

Tie Rod Installation Configurations - a pictorial overview of the two most common ways tie rods are configured.

Tie Rod Assembly Components - a diagram based overview of the components of a tie rod assembly.

Measuring Projects for Tie Rod Lengths - a step-by-step guide to measuring up your project to determine correct length of tie rods required. Includes diagram and simple formulas. Includes how to measure up for Single Pivot Point installations and Dual Pivot Point installations.

Ordering Tie Rod Lengths - a detailed example of how to select the correct size Tie Rod length from our website. Includes diagrams and a walk-through.

Tie Rod Installation Configurations

Here is a picture of a set of tie rods installed. The tie rod assembly connects to the steering column via a bracket at the bottom. Then those rods extend to the spindles / stub axles and control the rotation motion.

The tie rods can be assembled as shown below, or both tie rods can be fitted together on a single bolt in the centre of the column bracket (last picture – single pivot point installation).

DUAL PIVOT POINT INSTALLATION:

SINGLE PIVOT POINT INSTALLATION:

Tie Rod Assembly Components

The Tie rods themselves are simple alloy bars with a thread tapped through the centre. Generally the thread is only tapped into the rod about 50-60mm but because of the nature of the alloy it is relatively simple if more thread is required. This enables the user to reduce the length of the tie rod if needed, so you are much better off ordering a tie rod set which may be slightly too long, rather than one that is slightly too short.

Along with the tie rod itself, a complete assembly also contains a rod end (sometimes referred to as a rose-joint) and a lock nut to lock the position of the rod end. The lock nut can be loosened to allow the rod end to be screwed further in (reducing the overall length of the Tie Rod Assembly) or out (increasing the overall length of the Tie Rod Assembly).

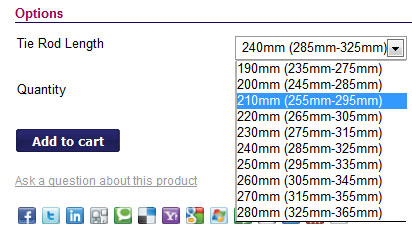

We offer the most common tie rod lengths – from 190mm to 280mm. This is the length of the Tie Rod itself (Rod Length).

Measuring Projects

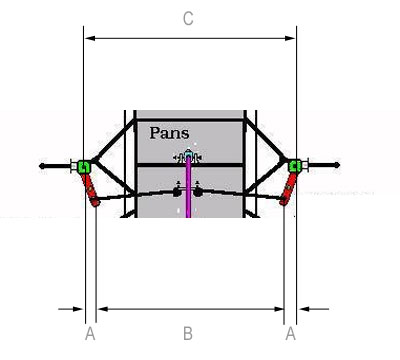

Re-ordering an existing size tie-rod is fairly easy, but it can be tricky to get the length right on a project if you have no idea where to start. So when deciding on the correct length of the tie rods, it is possible to get well within the adjustable length if you can obtain the distance from each of your kingpin holes (See the diagram below – measurement C) . Depending on the exact angles there can be a deviation of the distance around 10-20mm (See the diagram below – measurement A) but if you order on the slightly larger side, it is easy enough to reduce the length of the tie rod slightly given there is plenty of thread available.

Measuring tie rods for SINGLE PIVOT POINT INSTALLATION:

The easiest way to measure is in the case of the tie rods pivoting in the centre on a single point (like the last picture in the Tie Rod Install section). To obtain the length of tie rods required, simply measure the distance C above, then remove both A distances (if using our Stub Axles you will need to remove 2x 10mm = 20mm). Then divide by two, and choose a length where this value falls a little closer to the quoted minimum Tie Rod Assembly Length figures in the tie rod selector on our store.

EG:

C = 650mm. A=10mm. B=650-(2x10)=630mm

Tie Rod Assembly Length = ~315mm

We would recommend 260mm Tie Rods for this application [260mm (305mm-345mm)]

Measuring tie rods for DUAL PIVOT POINT INSTALLATION:

For dual pivot point applications, the process is the same as the single pivot point installation but the distance between the centre of the column and the points where the tie rods attach (See diagram above – measurement Y) must be deducted – this measurement is twice measurement X – the distance between the central and outer hole centres. To obtain the length of tie rods required, simply measure the distance C above, then remove both A distances (if using our Stub Axles you will need to remove 2x 10mm = 20mm). Then remove the distance Y (If using our shaft then use approx. 20mm) Then divide by two, and choose a length where this value falls as close to the middle of the quoted minimum and maximum Tie Rod Assembly Length figures in the tie rod selector on our store.

EG:

C = 650mm. A=10mm. Y=30mm, B=650-(2x10)-20mm=610mm

Tie Rod Assembly Length = ~305mm

We would recommend 250mm Tie Rods for this application [250mm (295mm-335mm)]

Ordering Tie Rod Lengths

When ordering steering components through our store, we provide both the raw length of the Tie Rod (Rod Length) first and the adjusted lengths (Tie Rod Assembly Length) second. We list both minimum and maximum lengths – Minimum length = Rod ends adjusted all the way in, Maximum length = Rod ends adjusted as far out as safely practicable.

Typically you will see these values in our store like this:

So the selected value above would buy you 210mm Tie Rod Length, which when assembled will give you a Tie Rod Assembly Length of minimum 255mm (rod ends wound right in) and maximum 295mm (rod ends wound right out)