GUIDE - TCCX# Torque Converter Fitment

GUIDE - TCCX# Torque Converter Fitment

GUIDE - TCCX# Torque Converter Fitment

You can find the smaller TCC12## install guide by clicking here

The TCCX converter is designed for large torque versions of stationary engines, such as 9hp and above. We have successfully used this model on up to 20hp engines without failure, although the more torque and more aggressively they are used, the more belts will be used as a consumable due to the added heat.

WHY DOESN'T THIS MODEL HAVE A MOUNTING PLATE?

This model of converter is designed to be used with an external jackshaft. While smaller torque converters can and do use a back plate with the jackshaft built right in, making it very convenient to mount, the bigger torque converters do not as a rule offer this option. The reason is the torque produced by the bigger capacity engine will bend and snap the back plate if not properly attached to a rigid surface. While there are some models in the USA offered with a backplate, it is not a reliable solution and eventually your plate will bend and/or snap due to the forces put on it from the engine.

We choose not to offer that solution as our parts need to be reliable and our reputation for being specilists in the 4-stroke field needs to be held above cheaper unreliable options. We recommend using the external jackshaft as per the one in our kit. It is not too difficult to fit and will ensure your vehicle is reliable and will not have a failure. Be wary of advice that a backplate style torque converter on a 9hp or larger engine will be reliable - that is simply untrue.

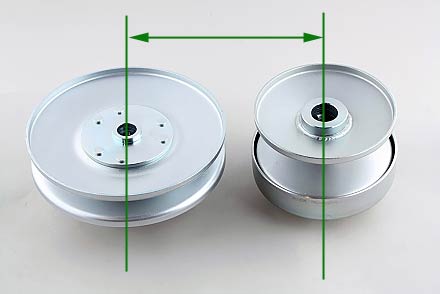

DRIVER AND DRIVEN PULLEY DIAMETERS

If you're trying to measure up your vehicle to see if you can fit one of these units, you can use the information below (pulley diameters) in conjunction with the distance measurement further down the page to provide dimensions for fitment.

Driver (engine) Pulley: approx 142mm

Driven (jackshaft) Pulley: approx 192mm

DISTANCE FROM DRIVER TO DRIVEN

Looking for the measurement between the crankshaft on the engine, and the jackshaft holding the driven pulley? The distance between the two centres of the TCCX high power torque converter should be 207mm

Craig Chaffey's installation looks super-tidy, using just the components inside the CPR TCCX kit:

When fitting our TCCX1C kit, here is a solution one of our clients came up with, using everything in the kit plus some additional spacer tube to space out the driven pulley from the jackshaft sprocket: