GUIDE - Why do i need an Aluminium Flywheel?

GUIDE - Why do i need an Aluminium Flywheel?

GUIDE - Why Do I Need An Aluminium Flywheel?

If you're contemplating, or have already removed a governor from a stationary engine, especially the honda GX range of engines (GX160 through to GX390/420) then your engine is most likely at risk of catastrophic failure including the chance of deadly injury to the driver and spectators.

Why?

Most 'cheap' stationary engines are delivered with a compromised steel flywheel. Stationary engines were only ever designed for a maximum RPM usage of 3600. The attached flywheels are well over-engineered for this RPM and can easily run practically forever but they are not designed to be reliable over this speed.

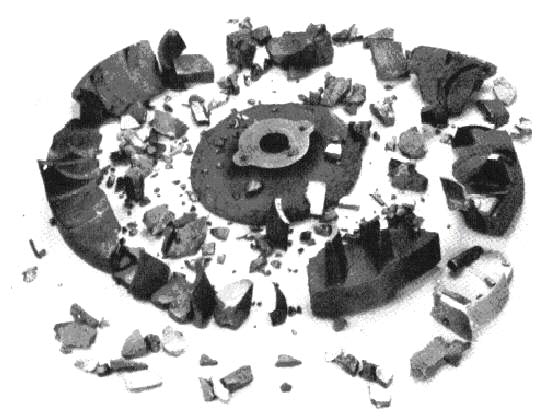

Standard flywheels are made from cast steel. At high speed revolution (in excess of the 3600rpm governed limit), the centrifugal forces acting on the wheel stretch it and create hairline fractures in the cast steel at weak points where the casting may have some impurities or voids (air bubbles). Once these fractures start, they begin to grow more rapidly - just like a crack in a windsheild on your car - until they finally completely crack. The flywheel then explodes like a grenade and sends shards of steel through your engine and into the air in all directions.

Some engines have better quality flywheels than others, but essentailly they will all fail at various points from 4000rpm up.

When you remove a governor, depending on the quality of the engine, it can rev in the range of 5000rpm up to 6500rpm. Most of the time the valve springs installed in a good quality well built engine willl restrict the rpm to a non-dangerous level but that is not true for all engines - espcially a $150 eBay special which will almost certainly include a low quality cast steel flywheel in which minimal care has been taken with the casting due to the purpose of pushing them out the door at a rock bottom price. Treat cheap eBay engines with care - just the removal of the governor alone will almost certainly cause the flywheel to detonate at high rpm. As a side note, installing high pressure valve springs (such as 18lb or 26lb springs in a GX200) will result in even higher RPM - so a valve spring upgrade with a standard flywheel is extremely dangerous.

It stands to reason then, that the best way to solve this issue is to use a flywheel that is either stronger, or lighter, or both. A lighter flywheel significantly reduces the centrifigual forces as the weight of the metal pulling itself outward is less so the force is less. Additionally, using CNC Machined billet (a solild block of material machined to shape) will increase the strength by ensuring that there are no impurities or casting voids (air bubbles) in the wheel.

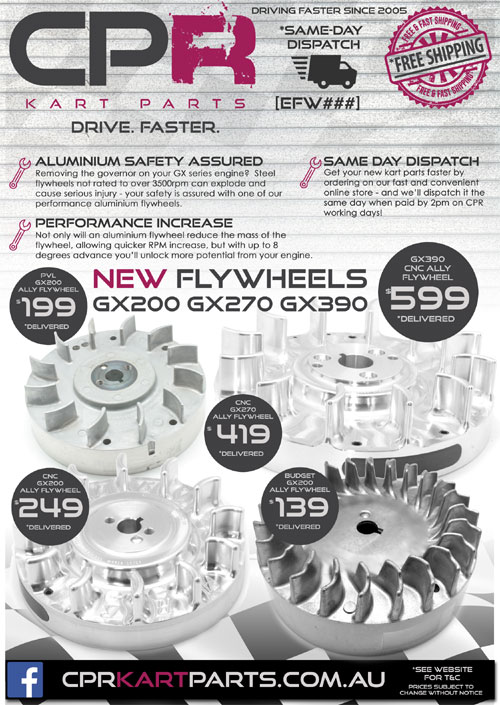

For engines running less than 11,000 RPM cast aluminium is generally strong enough, and many flywheels such as our stage 1 flywheel (CLICK HERE) has been tested in excess of this by US authorities (up to 17,000rpm) successfully for long periods of time without failure. So as a rule, for the vast majority of stationary engines being used as race engines a cast aluminium flywheel is sufficient.

There may be circumstances where a billet wheel is desired, and for premium builds it offers the absolute best quality at a price.

WHAT IS THE BEST ALUMINIUM FLYWHEEL FOR MY ENGINE?

That's a great question, and it does depend entirely on the level of your build. For a GX200 or GX160 If you're just removing the governor, installing a billet conrod (you can learn about why you should install a billet conrod by CLICKING HERE) and upgrading valve springs to 18lb +, then any of our cast aluminium flywheels will be more than enough to ensure a reliable engine.

Our entry level budget racer Almunimium Flywheel is a great value option and retains the stock timing - you can find it by CLICKING HERE

If you're looking for an additonal 4 degrees of advance (which is great for a bit of low down torque, but can increase heat in the combustion chamber adding to the chance of detonation) then your best option would be our Stage 1 flywheel - you can find it by CLICKING HERE

If you're looking for maximum strength, maximum RPM, and don't mind being super careful to avoid detonation, our 8 degree advanced billet Stage 2 wheel would be your best choice - you can find it by CLICKING HERE

HERE ARE LINKS TO ALL OF OUR STOCKED FLYWHEELS: