GUIDE - Protecting Valve/Rocker Cover Breather

GUIDE - Protecting Valve/Rocker Cover Breather

GUIDE - Protecting your open Valve/Rocker Cover Breather valve.

We're often asked the question "What do I do about the hole in my Rocker Cover now that I've installed an aftermarket air filter?" or "I just received a CPR 10hp 200cc engine and there's nothing where the hole in the Rocker Cover/Valve cover is - why is this open?"

This guide will explain what the hole is for, why it's there after the stock airbox is removed, and what you can do to further protect it if you like.

Do I really need to protect this hole?

Firstly, it is not critical to protect the hole. The stock airbox does protect it by closing the system but that is not the main function of the hose running from the hole to the airbox. The main reason it is there is to control emmissions. Leaving the hole open will generally not have any negative repercussions except if something very large lodges tight in the hole which may cause a pressure build up in the valve cover. The only thing this will generally do is stop the valves opening fully or vent out of the crankcase, potentially damaging a gasket. It won't do any serious damage to your engine but if the side gasket blows out you may experience an oil leak.

Why is it showing?

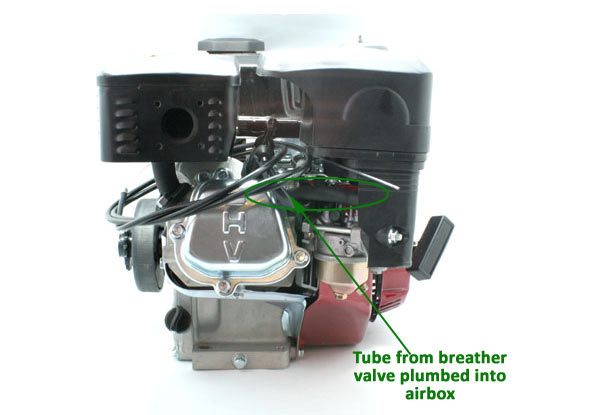

In a stock engine, the breather valve hole is plumbed back into the airbox, after the air filter and is then fed back through the carb into the combustion chamber to burn away. This is for the oil fumes to avoid them venting directly into the atmosphere. It's similar to how a blow-off valve plumb-back system works on a modern turbocharged car - it simply feeds the excess pressure back into the air inlet so that it can be re-used.

Here's a picture of a stock engine with the hose attached:

When you remove the stock airbox, there is no where for the rubber hose to plumb back into, so it's removed and you see the hole.

This hole is a port for a valve inside the rocker cover which releases positive pressure (a build-up of pressure inside the valve cover). You can see how the hole operates in the following picture of the rocker cover upside down:

BTW if you need a replacement valve cover because yours is damaged or the valve is not working correctly, you can find one by CLICKING HERE.

What's the best way to protect the hole?

If you want to do the job completely correctly, and comply with any rules both club and environmental, then it makes the most sense to consider at least an external filter system. You can get an easy to install one by clicking here

Is there a good cheap way to protect the hole?

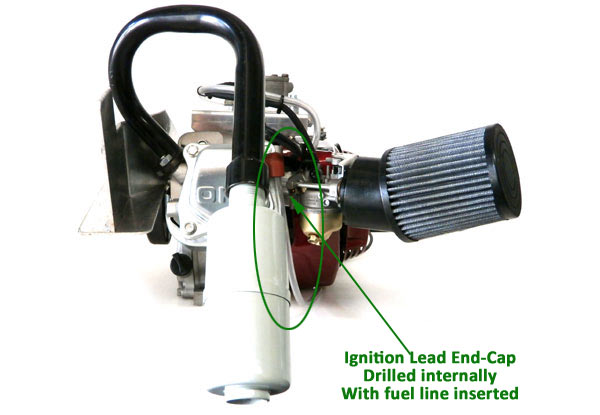

If you're looking for a lower cost option, the way our stage 2 performance race builds are done is to use a right-angle ignition lead end cap, drill the cap out and fit a piece of fuel line inside. That is then pushed into the open port/hole on the valve cover and the fuel line dangles down. This will allow pressure to release and vent into the atmosphere just like without it, but adds the protection of any airborne objects, stopping them from falling into the hole. The only way anything can get inside the port/hole is for it to travel up the fuel line (Not very likely). However, this does not include a filter and is more likely to fail where scrutineers are more critical of ventillation control. It's always best to use the complete filter system.

BTW if you need a replacement valve cover because yours is damaged or the valve is not working correctly, you can find one by CLICKING HERE.