GUIDE - Optimal Cylinder Head Temperatures

GUIDE - Optimal Cylinder Head Temperatures

CYLINDER HEAD TEMPERATURES - Why they matter & optimal temps for air-cooled race engines

Cylinder head temperatures are one of the easiest and most cost effective ways to measure the health of your engine on-the-go. When you're racing, you want maximum power at all times. The downside is that it's easy to push the engine a little past the optimal point, sending cylinder temperatures through the roof and in-turn causing seizure and other nasty damage to your engine.

There's really nothing more scary than locking an engine up at full speed down a straight. If you've ever experienced this, you'll know what we mean!

There's really nothing more scary than locking an engine up at full speed down a straight. If you've ever experienced this, you'll know what we mean!

This happens when the piston seizes or 'melts' into the bore, stoping the engine from rotating which in turn locks your wheels - it's like hitting the brakes with maximum force and them sticking on full.

Most engines perform best when the air fuel ratio is at a specific amount. We won't go into detail in regards to the ratio, but the important part is that a mixture with more air and less fuel burns hotter (a lean mixture) and a mixture with less air and more fuel burns cooler (a richer mixture).

So why not just make it rich, you say? Thereby solving the issue all together? Well that's a great idea in theory, the problem is that engines don't perform well when they are runnig a richer mixture. Again we won't go into the detail - you can find that information by googling - but the important part is that your engine will respond better and better the leaner the mixture at higher RPM.

When running an engine on the lean side of the fuel mixture, engines can get to a point where they perform phenominally but they become too hot, causing detonation which increases the heat even more - so hot that it literally melts the piston. Clearly this is bad, and needs to be avoided.

The best way to avoid engine failure is to keep an eye on your cylinder head temperature. In the past, the cost of equipment to do this has been very high - requiring a laptimer style unit in the region of $500 plus the sensor lead. CPR Kart Parts has developed a new low-cost unit which offers the ability to view the cylinder head temperature on the fly, check the maximum heat reached at the cylinder head during the race when you get back to the pits, and the abillity to set an alert to notify you of over-temp so you can back off or richen the mixture.

The best way to avoid engine failure is to keep an eye on your cylinder head temperature. In the past, the cost of equipment to do this has been very high - requiring a laptimer style unit in the region of $500 plus the sensor lead. CPR Kart Parts has developed a new low-cost unit which offers the ability to view the cylinder head temperature on the fly, check the maximum heat reached at the cylinder head during the race when you get back to the pits, and the abillity to set an alert to notify you of over-temp so you can back off or richen the mixture.

Here are some optimal temperatures for common air cooled engines:

CPR 10hp Style Engines - 220-230C

TORINI Clubmaxx - 230-235C

(on 4-stroke enignes, 0.01mm larger fuel jet = 5C reduction)

KT100S - 200-220C

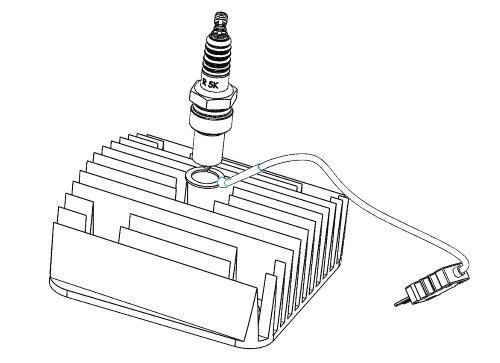

FAQ - TEMP SENSOR DAMAGE

. Several factors can cause them to fail including the following:

1. Over-Tightening the spark plug

a. If the plug is tightened down too much, the ring can easily twist and break. One solution can be to use a copper grease and a thin thrust washer between the ring and the base of the plug.

2. Multiple removal and installation of the plug

a. This is a common issue where plugs are being read. Unfortunately cylinder head temp sensors have the inherent issue where they are not designed to have plugs tightened and removed multiple times. Ideally it should be a set and forget solution. However, in practice this is hard to achieve. We recommend using copper grease and a thin thrust washer between the ring and the base of the plug.

3. Modifying the orientation of the fly lead from the sensor ring

a. Sometimes it may be desirable to twist or bend the sensor ring fly lead to avoid fins or other obstacles, or to try to avoid hot surfaces. While this is not recommended as it can damage the sensor, if you are doing this it is best to heat the ring prior to trying to bend. Bend the lead slowly and gently until it has reached the desired shape. It is definitely possible to break the lead this way so take your time. Damage in this way is not covered under warranty.

4. Surface inconsistency (divots/damage/dags/lips/debris/other sharp protrusions) on cylinder head, plug thread, or plug base

a. Check your head, plug thread and plug base that they are all smooth and free from any debris that may catch on the sensor ring – this can rip the sensor ring easily.

5. If all else fails

a. CPR Kart Parts carries replacement sensor rings for all CPR temp gauges which can be found in the store in the gauges section.